More Crop per Drop

OPTIMIZE IRRIGATION WATER USE

The primary agricultural irrigation system in Georgia is the center pivot irrigation system. Approximately 23,000 center pivot systems are located across the state, mainly below the Fall Line. Drip irrigation is also utilized in vegetable and orchard production statewide. Other forms of irrigation that are not as common include solid set sprinklers and traveling guns.

Some of the practices described below, such as remote control and irrigation scheduling, apply to any type of irrigation system. The other practices, such as retrofits and variable rate irrigation, are more specific to center pivot irrigation.

Enhance on-farm efficiency

Smart Irrigation tools range from simple and free to complex and costly. The best management practices described below are available to farmers in Georgia. Each practice includes a brief description, examples, an estimated cost, and approximate gains in water use efficiency or water savings. Note: water use efficiency refers to the amount of water pumped that is utilized by the crop (more crop per drop), and water savings refers to actual water conserved from reduction in groundwater withdrawal. The estimates below are not necessarily additive as each efficiency and savings scenario is dependent on individual field conditions and management decisions.

RETROFITS

Convert HIGH PRESSURE sprinklers TO LOW PRESSURE

Irrigation Retrofits

evolution of efficiency

Farmers began implementing center pivot irrigation systems in Georgia in the 1970’s, and the conventional models operated at high pressure with impact sprinklers spraying water from the top of the pivot mainline. Converting these systems from high to low pressure with spray-type sprinklers on drop hoses generates considerable water and energy savings. By applying water at a lower pressure more directly to the soil surface, the low pressure system significantly reduces evaporation and wind drift losses.

Today’s low pressure spray-type sprinklers are designed to produce a very uniform application of water droplets over the field. In combination with drop hoses, these sprinklers help to reduce losses to wind drift and evaporation by applying water closer to the crop in larger droplets. High pressure impact sprinklers, in comparison, spray the water much higher in the air with smaller droplets. Also, low pressure spray-type sprinklers are unique in the fact that they operate between 10 to 30 pounds per square inch (psi) allowing them to have a lower energy requirement.

A center pivot irrigation system with high pressure sprinklers. (Calvin Perry/UGA)

A center pivot irrigation sprinkler with low pressure drop-nozzle sprinklers. (Casey Cox)

Efficiency

The high pressure system has an average efficiency of 60%, due to water losses from evaporation, wind, and drift. Combined with the installation of end-gun controls to keep irrigation inside the field boundary and the repairing of leaks in the system, retrofitting a pivot may increase water use efficiency to 80 - 90%.

ESTIMATED COST

Converting an existing system from high pressure to low pressure costs range from approximately $2,500 to $5,000. Most new center pivot systems are equipped with low pressure drop hose sprinklers.

REMOTE CONTROL

manage irrigation from anywhere

Remote Irrigation Control

monitor irrigation from phone or web

Farmers have spent countless hours and tanks of gas at all times of the day and night driving back and forth to fields to check irrigation systems. With this remote control technology, a farmer can now save time and fuel with the ability to remotely monitor and control irrigation systems from their phone or computer.

This technology controls multiple aspects of the system remotely: turn on, turn off, change direction, set a timer for the system to start, control the end-gun sprinkler with precision by degree, check the position of the system, set the stop for a precise angle, and even speed control variable rate irrigation on certain systems. All systems enabled with this technology are available on a singular dashboard and even connected with some soil moisture sensor systems transmitting real-time data from the field.

This technology is available for both center pivot and drip irrigation systems.

estimated cost

Remote pivot control systems vary by product but generally range from $2,000 - $5,000 per system with an annual subscription fee in the $300 range.

Efficiency

No official studies have been done to approximate the efficiency of remote control technology for irrigation systems. Any increase in efficiency is highly subjective by field and producer. The ability to stop the system at precise angles, control the end-gun by degree, and set automatic timers to start and stop the system take limitations on timing out of irrigation management (e.g. if the farmer is unable to arrive at a system at the precise moment it needs to be stopped).

IRRIGATION SCHEDULING

KNOW WHEN AND HOW MUCH TO IRRIGATE

WHAT IS IRRIGATION SCHEDULING?

analyzing real-time field data to optimize irrigation application decisions

Irrigation scheduling helps determine when to irrigate and how much water to apply.

Irrigation scheduling can optimize plant growth, crop yield, crop quality, nutrient management, root zone health, and irrigation decisions.

smart irrigation apps

A screenshot of the Smart Irrigation app developed by UGA & UF

The University of Georgia and University of Florida have collaborated on a project to develop Smart Irrigation apps for both iOS and Android for several different agricultural crops. Currently available apps include Cotton, Soybean, Citrus, Strawberry, and Avocado. Corn, Peach, and Blueberry are in the development/field validation process and will be publicly released in the next couple of years.

Each app generates irrigation recommendations for its specific crop according to the particular characteristics and phenology of that crop. The concept of Smart Irrigation Apps is to keep a simple range of inputs (that producers can reasonably answer) that will then be used to run a Soil Water Balance model based on estimated water loss (Evapotranspiration), crop and region specific coefficients (KC) and observed and forecasted weather data (from Weather Stations, National Weather Data Grid, and more recently for some apps (Cotton and Soybean) Automated Rain Sensors).

One of the most useful features of the app is the ability to receive notifications when irrigation is needed, rain events are observed in the field area, and approaching phenological stages.

While the project started supporting only Florida and Georgia producers (due to the availability of automated weather stations networks (Georgia Automated Environmental Monitoring Network (GAEMN) and Florida Automated Weather Network (FAWN) ), a few of them are now expanding to other producing regions in the United States by using National Weather Data Grid sources.

Irrigator Pro

Irrigator Pro is an irrigation scheduling tool for peanuts, corn, and cotton developed by the USDA Agricultural Research Service National Peanut Research Lab. Irrigator Pro is an expert system designed to provide recommendations based on scientific data resulting in conservation-minded irrigation management while maintaining high yields.

The Flint River Soil and Water Conservation District, with funding from USDA NRCS, partnered with the Peanut Lab and University of Georgia to develop a smartphone app and cloud-based platform for Irrigator Pro.

Irrigator Pro is a trusted tool by farmers, crop consultants, Extension agents, and researchers across the Southeast. The original version is a desktop software that requires manual reading of soil moisture sensors in the field and manual data entry. The new smartphone app and cloud platform have automated the data collection process, integrating remote upload of soil moisture and temperature data with the Irrigator Pro model through the app and cloud platform.

soil moisture sensors

Soil moisture sensor in peanuts (Casey Cox)

The purpose of a soil moisture monitoring system is to deploy probes or sensors in the field to detect soil moisture conditions which are critical to optimal crop production. Monitoring soil moisture status allows the farmer or consultant to prevent plant stress by managing irrigation and rainfall to maintain soil moisture at optimal levels. Soil moisture sensors provide a gauge of current field conditions to determine if there is adequate moisture for the crop, if the soil is drying, or if the soil is very dry.

types of sensors

A multitude of commercial sensors exist on the market. They fall in to two primary categories: tensiometric and volumetric (or capacitance).

Capacitance probe uses special capacitor related sensors to measure “volumetric” soil moisture. The volume of water in the total volume of soil most heavily influences a soil parameter called the dielectric permittivity of the soil.

When the amount of water changes in the soil, a sensor will measure a change in capacitance due to the change in dielectric permittivity that can be directly correlated with a change in soil water content. Result provided is the water content in the soil – the volumetric soil water content. These sensors must be calibrated for the specific soil where installed.

Tensiometric soil moisture sensors measure “matric water potential” or soil water tension. Soil water tension is the amount of energy or ‘suction’ that a plant’s roots must exert to extract soil water. With an electrical resistance sensing device, as the tension changes with water content, the resistance changes. The change in resistance can be correlated to soil water content. Result is given in centibars or kilopascals of soil water tension. These sensors do not require site-specific calibration.

estimated cost

Smart Irrigation Apps: Free

Irrigator Pro: Free (but requires soil moisture and soil temperature data from a sensor to make irrigation recommendations)

Soil moisture sensors: Varies widely. A simple sensor and a monitor to hand read it may cost less than $100. It would be important to factor in the cost of time in hand-reading a soil moisture monitor daily. More sophisticated systems that include telemetry where farmers can access the soil moisture data from anywhere range from $900 - $4,000.

efficiency

Water savings are generated by identifying precise periods of time in which a farmer can reduce irrigation by using objective field data such as soil moisture, soil temperature, crop growth stage, and localized evapotranspiration. Advanced irrigation scheduling may reduce water use by 15% on average.

Advanced Irrigation Scheduling for Agriculture video

END GUND CONTROLS

SETTINGS FOR CENTER PIVOT END GUNS

WHAT ARE END GUN CONTROLS?

Controls to optimize END Gun irrigation uniformity and efficiency

The end gun is a large sprinkler located on the end of center pivot irrigation systems that can extend irrigation from 80 to 100 feet on average.

Proper end gun irrigation application can optimize plant growth, crop yield, crop quality, nutrient management, root zone health, and irrigation decisions.

End Gun Controls

Proper end gun irrigation offers a low cost way for farmers to easily irrigate additional acreage that doesn’t fall under center pivot sprinklers. When set correctly, end gun sprinklers offer slow, steady and uniform irrigation. When end gun applications are not properly set, it will result in wasted irrigation water and pumping costs.

Center pivot system and end gun in a peanut field. (Calvin Perry)

Incorrect end gun application can typically be an easy fix. Setting the end gun at proper angels, ensuring uniform application, and setting the springs in the flapper to manage speed are all critical in optimizing end gun efficiency.

Uniformity tests, which are conducted by setting up buckets every 10 to 20 feet outside of the end of the pivot, are a simple and cost effective measure of uniformity.

Pivot and field specific considerations should also be taken into effect when determining proper end gun settings. If adjusting settings doesn’t result in improved end gun efficiency, ensure you have the correct end gun installed for the system and that the nozzle is not worn.

End Gun Shut Off

End gun spraying into roadway. (Calvin Perry)

While often end gun sprinklers are used to extend irrigated areas beyond the center pivot, in some cases end gun sprinklers may irrigate areas that do not require irrigation. This includes areas such as wooded areas, roadways, in field wetlands or other non-cropped areas.

End gun shutoff controls allow growers to identify areas along the circumference of the center pivot system that do not require irrigation. Shutting off end gun irrigation saves water, pumping costs, and reduces farmer liability by ensuring non-cropped areas are not under an end gun spray.

estimated cost

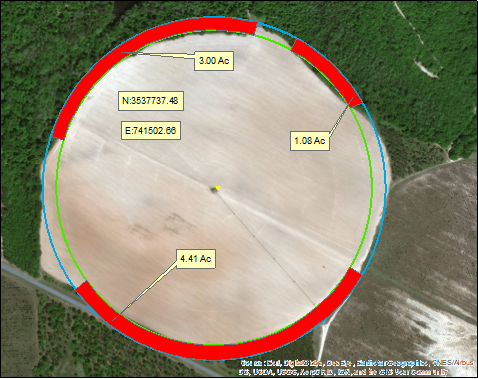

A screenshot of End Gun shutoff acreage. (Tony Black)

Uniformity tests are a low-cost way to determine if end gun settings need adjustment. Reach out to your local county extension agent or soil and water conservation district for free uniformity test options. Specific fixes to end gun controls range from free settings adjustments to nozzle replacements.

End gun shutoff retrofits for pivots that do not have existing shut-off controls cost an estimated $2,500.

efficiency

Water savings from pivot end gun controls are specific to the individual field, crop, and surroundings.

End gun shut off technologies may save a significant amount of water, depending on crop and acreage in the shut off area. Approximately 216,000 gallons per acre are saved in peanut fields, 345,000 gallons per acre in corn fields, and 371,000 gallons per acre in cotton fields (estimates based on UGA Extension data presented by Tony Black). Shut off area is specific to each individual field conditions and surrounding areas.

VARIABLE RATE IRRIGATION

CUSTOMIZE WATER APPLICATION WITH GPS

Variable Rate Irrigation (VRI)

PRECISION IRRIGATION

A center pivot system is retrofitted to control irrigation application with GPS guidance by span or individual sprinkler, depending on the type of VRI system.

With VRI, the center pivot applies varying amounts of water across irrigation management zones to address variations in the field, helping farmers determine where to irrigate.

VRI enables farmers to apply customized rates of water based on individual management zones within a field. VRI has economic, agronomic, and environmental benefits. Enhancing the precise placement and amount of irrigation through VRI can conserve water and reduce input costs. VRI improves water use efficiency by irrigating precise amounts according to soil and crop needs. Using VRI conserves water, and it may also reduce runoff and leaching of nutrients.

SPEED CONTROL OR ZONE CONTROL

There are two ways to implement VRI: speed control or zone control. Speed control VRI divides the field into pie slice-shaped sections, and the user can vary the speed in each of these sections. Zone control VRI divides the field into irrigation management zones that are delineated on a software-based mapping program and then uploaded to the pivot.

Irrigation Management Zones are delineated based on soil types, topography, hydrology, and other features. With VRI, the center pivot applies varying amounts of water across the irrigation management zones to address variations in the field, helping farmers determine where to irrigate. The animation above demonstrates how VRI operates across variations in a field.

estimated cost

The cost of VRI varies significantly. Speed control VRI is often a feature of remote irrigation tools and is included in a suite of other tools for $2,500 - $5,000. For zone control VRI, farmers do have the options of installing a partial or modular VRI system (only implementing GPS controls on a specific set of sprinklers rather than the full system). Partial VRI expenses range from $5,000 - $15,000. A full VRI system may cost anywhere between $20,000 - $45,000 depending on the length of the pivot.

efficiency

Researchers have determined VRI may reduce water use by 15% on average. This also varies greatly depending on field conditions and VRI management.

Variable Rate Irrigation for Agriculture video

DYNAMIC VARIABLE RATE IRRIGATION

AUTOMATE IRRIGATION PRECISELY WITH REAL-TIME FIELD DATA

Dynamic Variable Rate Irrigation (VRI)

HOLISTIC PRECISION SYSTEM APPROACH

Dynamic VRI is a practice that is still on the cusp between research and commercialization. Dr. George Vellidis of the University of Georgia describes it as “a tool that will allow us to improve the sustainability, efficiency, and profitability of our irrigated farming systems.”

An example of how dynamic VRI could appear on a “dashboard” for farmers to schedule when, where, and how much to irrigate.

SMART IRRIGATION integration

Dynamic VRI combines many of the above elements into a precision irrigation system that utilizes real-time field data to apply the needed amount of water at the right time in the right location for optimal crop growth and development.

Standard VRI maps are static, meaning that the irrigation management zones and water application rates are uploaded to the irrigation system infrequently. Dynamic VRI enables the farmer to utilize real-time soil moisture data to update water application rates by zone for each irrigation application.

The field above is divided into “strips” of management zones: dynamic VRI (multicolored) and traditional (solid). In this study, the farmer determined the amount of irrigation applied in the solid strips, and the UGA team prescribed rates in the dynamic VRI zones based on real-time data.

Some types of Dynamic VRI require a high density soil moisture sensor system within the field. Each gauge above represents a sensor located within a different irrigation management zone.

Estimated cost

The price for dynamic VRI includes a full VRI system with remote upload capacity, which may range from $20,000 - $45,000, depending on the size of the system and type of VRI. Additional costs include a high density network of soil moisture sensors ($10,000 - $15,000). Dynamic VRI also works best with in-depth field analysis of soils and electric conductivity, which add additional varying expenses. It may also take more time and intensive management from the farmer, crop consultant, or irrigation manager which is another factor that must be considered. There are commercial versions of this technology available that do not incorporate the high density soil moisture sensor network. More details and comparisons will be available in the future.

Efficiency

Research conducted by researchers at the University of Georgia in partnership with the Flint River Soil and Water Conservation District has shown that the integration of Dynamic VRI technology may increase water use efficiency by up to 40% while increasing yields between 5 and 10% compared to traditional irrigation methods.

Banner photographs and videos courtesy of Matt Hanner, Calvin Perry, and National Peanut Board.